Main characteristics of Technora:

Strong and light: weight for weight, Technora is 8 times stronger than steel and 3 times stronger than fiberglass, polyester or nylon yarns.

Shows little loss of strength even during repeated abrasion, flexing and stretching.

Stiff and highly oriented molecular structure leads to a high modulus of elasticity, low creep and low stress relaxation. Low thermal shrinkage, i.e., excellent dimensional stability.

Thermal decomposition threshold of 500ºC, so Technora can be used at 200ºC for long periods. At 250ºC, it maintains more than half of its room-temperature tensile strength.

Highly resistant to acids, alkalies and organic solvents; not vulnerable to damage caused by steam or sea water.

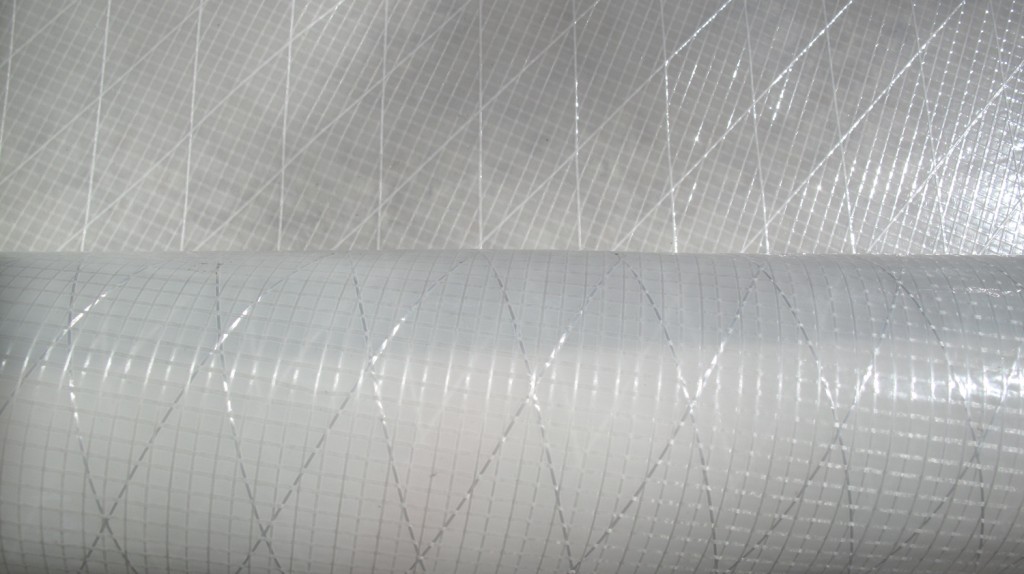

Tri-Lite Scrim Characteristics:

- The Tri-Lite consists of a closely space woven polyester scrim and X ply that is laminated with thin film on both sides.

- The overall weight is about 40% less than monofilm.

- The tear strength is much better than standard X ply because of the combination of scrim, X ply and the thinner film.

- The Tri-Lite also has 2 to 3 times better UV strength because the thinner film does not get as brittle as thicker films do when baked in the sun.

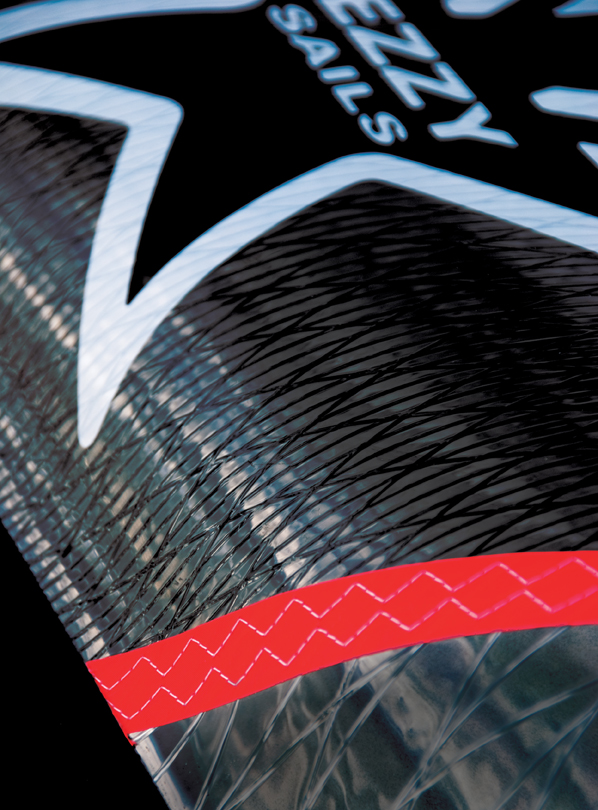

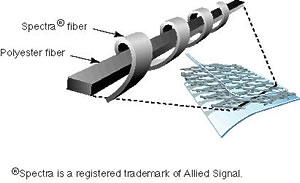

Spectra® X-Film

Our Spectra® X-Film, with its super-tough Spectra® Yarns laminated between two layers of film, has 1,000 times stronger tear strength and better UV resistance than monofilm.

David Ezzy’s own triaxial rip-stop film that now sets the standard by which all other sail materials are measured. The new x-ply laminate material utilizes a Spectra® yarn. Braided with a polyester filament, in a wide triaxial grid, the results are astonishing.

Due to the wider grid pattern, this material weighs less than our previous x-ply film, thus reducing the sails’ overall weight. A benefit to surf sailors and swell riders, the Spectra laminate also offers improved visibility and five times the rip-stopping power of traditional x-ply laminate films. This has resulted in a revolutionary material which boasts an unprecedented strength-to-weight ratio.

The Spectra® laminate film is found in the Ezzy Wave Special Edition, the Ezzy Infinity, and the Ezzy Eagle Kids Sail.

Endobatten Shaping

The shaping in our sails is done in every panel along with the luff curve. There is shape in every panel and every panel overlaps to create a batten pocket. Doing this we can make the draft in the sail move forward.

Other company’s sails, the draft moves back when you sheet in. This creates a constant pull on your backhand.

Unparalleled R&D

10 months out of the year we are designing, making and testing prototypes for the next year’s sails. We make almost a sail a day. Other companies make 1 sail a week or every two weeks.

We test our sails in a variety of conditions on Maui. We are constantly trying new ideas and materials to make our sails better than the rest.

Finest Manufacturing Standards Available

Every Ezzy Sail is assembled by David Ezzy’s own factory. This means the quality control is set up to his exacting standards. Every sail is rigged before it leaves the factory to make sure every seam is flawless.

When the sails are being made in the factory, every one is rigged and checked for quality.